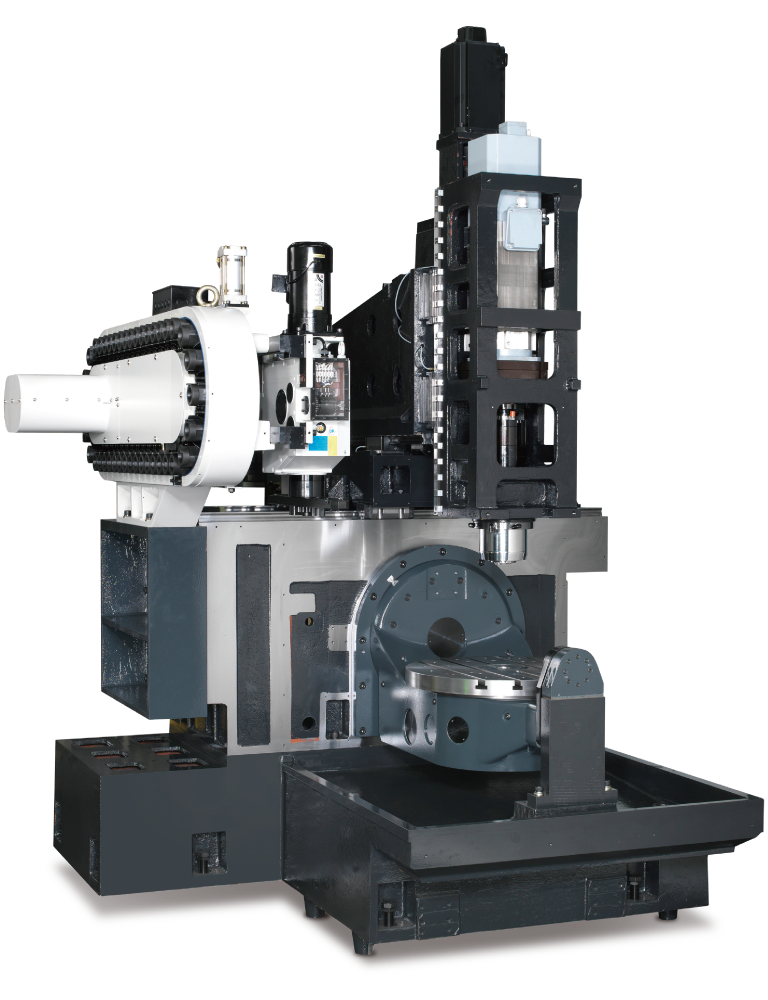

5 AXES SIMULTANEOUS CONTROL

Easy loading of workpiece, efficient smart management, good operating ergonomics all axes servo driven, encoder feedback on all axes, optional auto door, optional workpiece clamping (oil/air), optional ball screw nut, cooling, finite analysis design, high rigidity cast construction.

THK linear guideway (JAPAN) X, Y, Z.

CUSTOMER CAN CHOOSE A DIFFERENT DRIVE METHOD ON B/C AXES

Cam Drive (Standard)

Worm Drive

Direct Drive

Standard

- Spindle speed 12000rpm

- Spindle oil chiller

- Spindle bearing purge

- Programmable cutting air blast system

- Coolant gun

- Air gun

- Full enclosed splash guard

- Large table size 650mm

- Interlock front/ side door

- Mechanical oil/coolant separator

- Automatic tool changer

- Spindle taper: #40(DIN, BT, CAT)

- 32 station tool magazine

- Roller linear guideways

- Z-axis motor with brake system

- LED lamp

- M30 power off

- Heat exchanger for electrical cabinet

- Tailstock for GTX-1520 / 2520

Optional

- Coolant Through Spindle (CTS)

- Programmable cutting coolant nozzle

- Coolant cooling system

- Chain type chip conveyor

- Chip cart

- Chip flushing system

- Laser tool length measurement system TL Micro 200

- Contact type tool length measurement system TT160

- Workpiece measurement kinematic system TT740+KKH100(250)

- Air supply for clamping fixture

- CE conformity specification

- Round metal plate type oil skimmer

- X / Y / Z optical linear scale

- B / C-axis optical encoder

- Air conditioner for electrical cabinet

- Transformer

- HSK 63 20,000rpm spindle (Built-in type)

- 15000rpm direct driven spindle

- Software for crash protection

- Mitsubishi M80, M830

- Fanuc 0iMF, 31i

- Siemens 828D, 840D

- Heidenhain TNC620, iTNC640

- Fagor